Advanced Automation

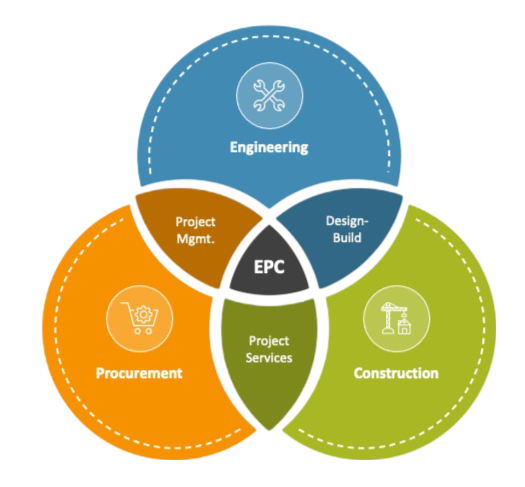

EcoTrust for Technology Solutions offers comprehensive consultation and contracting services for Engineering, Procurement, and Construction (EPC) projects. Our integrated engineering solutions are designed to meet the specific needs of our clients, leveraging the latest technologies and methodologies to ensure optimal performance, sustainability, and cost-efficiency.

Importance of Advanced Automation Solutions

Advanced automation is crucial component in modern EPC projects for several reasons:

- Efficiency: Automation streamlines processes, reducing time and labor costs.

- Precision: Enhances accuracy in design, construction, and operation, minimizing errors and rework.

- Sustainability: Optimizes resource use, reducing waste and environmental impact.

- Safety: Improves safety by minimizing human intervention in hazardous environments.

- Scalability: Facilitates the scaling of operations to meet increasing demands.

EcoTrust TS’s Key Areas of Expertise

Infrastructure & Construction Industries

- Cement Plants: Implementing automated systems for material handling, mixing, and quality control to ensure consistent product quality and operational efficiency.

- Steel Plants: Utilizing robotics and AI for precision in steel production, reducing energy consumption and improving safety.

- Porcelain Plants: Automating the production process to enhance product consistency and reduce defects.

- Aluminum Plants: Integrating advanced automation for smelting and casting processes to improve efficiency and reduce emissions.

- Carbonaceous Material Plants: Employing AI and robotics for precise control of production parameters, ensuring high-quality output.

- Power Generation Stations: Implementing smart grid technologies and automated control systems to optimize energy production and distribution.

- Steam Generation Stations: Utilizing advanced monitoring and control systems to enhance efficiency and safety.

- Industrial Water-Cooling Circuits: Automating the monitoring and control of cooling systems to ensure optimal performance and energy efficiency.

By staying abreast of industry trends and policy developments, we ensure that our clients are not only compliant but also ahead of the curve in sustainability innovation.

Life Industries

- Food and Beverage Processing Plants: Integrating automation for processing, packaging, and quality control to ensure product safety and consistency.

- Pharmaceutical Factories: Utilizing robotics and AI for precision in manufacturing and quality assurance, ensuring compliance with regulatory standards.

- Intelligent Sustainable Farms: Implementing automated systems for irrigation, cultivation, harvesting, and post-harvest processing to enhance productivity and sustainability.

Mining

- Accelerated Reserve Exploration: Using big data analysis, intelligent remote-sensing analysis, and precise physical exploration techniques to identify and evaluate mineral reserves efficiently.

- Ore Dressing: Automating the separation and concentration processes to improve efficiency and reduce environmental impact.

- Metals Recovery: Implementing advanced technologies for the recovery of valuable metals from ores, enhancing resource efficiency.

- Ore Concentration Processing: Utilizing automation to optimize the concentration process, ensuring high yield and quality.

Distinguishing Features of EcoTrust’s EPC Services

EcoTrust stands out in providing EPC services through:

- Expertise in Advanced Automation: Leveraging AI, robotics, and advanced automation technologies to deliver cutting-edge solutions.

- Human-Centric Approach: Ensuring that automation solutions are designed with a focus on human-centric principles, enhancing decision-making and user experience.

- Sustainability Focus: Prioritizing environmentally friendly and sustainable techniques, using safe materials, and minimizing energy demand and carbon footprint.

- Innovative Technology: Utilizing genuine software compliant with the fifth industrial revolution (I5) and conducting realistic simulations to achieve the best feasibility.

Professional Steps to Deliver EPC Services

- Requirement Analysis: Conduct a thorough analysis of customer requirements and expectations.

- Design and Product Selection: Use Product Life Cycle Management (PLM) mechanisms to design and select the best products.

- Simulation and Feasibility Study: Conduct simulations using advanced software to process big data and achieve optimal feasibility.

- Implementation: Integrate AI, robotics, and advanced automation in the construction process, ensuring safety and efficiency.

- Testing and Validation: Perform rigorous testing and validation to ensure the solution meets all specifications and standards.

- Deployment and Support: Deploy the solution and provide continuous support to ensure smooth operation and maintenance.

Delivery Duration

The delivery duration for EPC projects varies depending on the complexity and scope of the project. Typically, it ranges from 3 to 12 months.

In EcoTrust TS with our partners focus on the following significant engineering and technical aspects in our integrated engineering solutions:

- Integration of AI and Robotics: Highlighting the use of AI and robotics in enhancing precision, efficiency, and safety.

- Sustainable Practices: Emphasizing the use of sustainable materials and techniques to reduce environmental impact.

- Human-Centric Design: Showcasing how human-centric principles are integrated into decision-making and control systems.

- Big Data and Simulation: Demonstrating the use of big data analysis and realistic simulations to optimize project feasibility and outcomes.